Markets

The MGS Group equipment is in use all over the globe in a wide variety of markets

Power Cables

Power Cables are in demand today. Worldwide infrastructure, wind and solar developments are driving growth within this sector. The MGS Group has been solving manufacturing challenges in this market dating back to the origins of the company. With The MGS Group headquarters and main manufacturing facility in Rome, NY, the company is located amid traditional major wire and cable manufacturing facilities of Central New York, USA. The MGS Group offers solutions for power cable material handling such as pay offs, takeups and other machines/accessories that address requirements in the wire forming, extrusion and packaging processes.

Bare Wire Fabrication

The MGS Group Companies have various connections with the manufacture of bare wire. From wire handling – payoffs and take ups to bunching machines, The MGS Group assists bare wire manufacturers to efficiently produce their products world wide. Wire manufacturing is a basic industry in any industrialized country and The MGS Group has been a presence in this market since the early days. We remain active in this industry as well as exotic metal manufacturing where close tolerance techniques is of primary importance. The MGS Group makes machines and accessories that address needs in bare wire fabrication.

Fiber Optics

Fiber Optic cables are the backbone of our communications network today. Voice and data communications rely on Fiber Optic cables to transmit the vast quantities of data along with voice and video that are vital to today’s social and on-demand culture. Our globally connected world relies on the flawless transfer of data. Optical Fiber products are sensitive and fragile during the manufacturing process, requiring specific attention and expertise in order to handle successfully. To address the demands inherent in handling the components of these cables, The MGS Group has provided machine solutions incorporating leading edge tension control capabilities solving complex issues in the construction of fiber into ribbons, loose tubes, buffer tubes, and other cable constructions.

Plastics

Plastics extrusion is diverse and complex. Many agricultural, consumer, industrial and construction applications are serviced by plastic extruded products today. The MGS Group addresses material handling equipment and most notably packaging solutions for these applications. The MGS Group offers Fully Automatic Coiling solutions that are flexible and customizable to address customer needs. Our success in applications based solutions stem from our engineered product approach. Our engineering department takes standard packaging system designs and customizes our capabilities to meet specific customer needs.

Rubber Hose

Rubber hose manufacturing has evolved in the past years with the level of technology increasing to address challenges within demanding markets. Greater attention to sustainability, reducing VOCs, increasing burst performance, hybrid designs and more, have increased demands on manufacturing. Today’s extrusion process demands greater attention to tension control and overall line stability in order to produce highly engineered products. The MGS Group knows line control and how to handle products with care in the extrusion process. Let our experience benefit your process challenges. We deliver engineered solutions based on your requirements.

Medical Tubing

Medical markets demand traceability and accountability. Precision and accuracy of the process is dependent on line stability. Sensitive extrusion process tension control is critical to achieving the desired material geometries. Precision process control mandates precision tension control, The MGS Group has developed leading edge solutions for tension sensitive applications. We offer a range of product handling machinery suitable for addressing processing of hose, tubing, multi-lumen tubing, fine wires and other medical specialties.

Specialty Metals

Specialty metal manufacturing requires unique approaches to process handling. Magnet wire and other shaped wires require specialized handling to avoid deformation of desired profiles. Exotic and precious metals processing demand tension control and handing care. Whatever the processing requirement, The MGS Group can work with your requirements and develop long lasting, robust solutions that will stand the test of time. Our rugged solutions meet your process challenges.

Building Wire

From new construction to DIY, building wire is a tremendous wire and cable market without boundaries for growth. The MGS Group offers a vast variety of products for demands in the manufacture of building wire products. We offer bunching, stranding, cabling machines, payoffs, takeups, capstans and everything in between for your building wire processes. The trademark rugged build of our products delivers long term performance for your success. Performance and long lasting machine design drives our success in this market. Shown here is the FAT820, our Fully Automatic Takeup System.

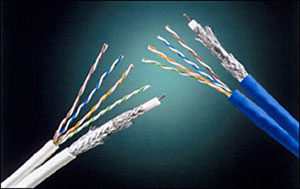

LAN Cables

LAN Cables, Category types 3,4,5,6,7++. All benchmarks for production demand techniques that far surpass traditional wire and cable production. Attention to tension and construction details are a must throughout the process. Without this attention to detail product performance simply cannot be achieved. The MGS Group companies have been on the forefront of this market successfully addressing these process demands. We take an engineered approach to each technical application. Each manufacturer in this market approaches their processes differently, therefore we adapt machine capability specifically to meet the needs of our customers insuring final product performance.

Oil and Gas

The Oil and Gas markets includes a broad range of products from subsea umbilical cables, seismic survey, wireline service cables, downhole pump power cables and more. These cables involve great engineering detail for the demands of the environments they operate in. Manufacturers in this market adapt their capabilities to the new designs they develop resulting in requirements of flexibility in the machines they use in their processes. The MGS Group works with the customer to design our equipment to meet the challenges of today and tomorrow.

Coaxial Cables

Coaxial cables provide high bandwidth communications supporting television transmission to demanding aerospace communications systems. The MGS Group has provided engineered solutions to meet these demands. The MGS Group provides solutions from the extrusion to packaging operations for these products. Similar to the demands seen in category cable applications, specific capability has to be engineered into the process machinery to address structural return loss concerns with the final cable constructions.

Radio Frequency Cables

RF cables support high bandwidth communications networks. Basically, the king of coaxial cables, the RF Cable construction are demanding in many respects. The cable is often times a foamed construction requiring specialized techniques and process know how. The handling of the cable in manufacture requires steady and consistent movements to insure the cable performance. The MGS Group machinery has insured smooth and steady cable handling throughout these processes. We have provided a range of payoffs, takeups and capstans for applications in this field.

Metal Tubing

From basic to precious metal tubing, The MGS Group attention to tension control process stability insures the integrity of the product is delivered to the end user. We have provided solutions for tubing applications in a variety of applications. Pictured here is takeup laying the final product onto a reel for delivery to the customer.

Heat Shrink Tubing

Heat shrink tubing has special characteristics to accomplish its job in the electrical world. The forming process for this material is a sensitive operation as well the packaging of these products after the manufacture demands care. The MGS Group range of products is designed for specialized attention to tension and lay control for working with heat shrink tubing.oup offers a vast variety of products for demands in the manufacture of building wire products. We offer bunching, stranding, cabling machines, payoffs, takeups, capstans and everything in between for your building wire processes. The trademark rugged build of our products delivers long term performance for your success. Performance and long lasting machine design drives our success in this market. Shown here is the FAT820, our Fully Automatic Takeup System.

Conduit

Construction, building, and industrial applications are increasingly specifying cables in conduit for a variety of applications. More attention to safety and increased protection from moisture and the elements have driven demand for conduit clad wire products. We work with metallic and nonmetallic conduit designs for a range of handling equipment requirements. The MGS Group Autocoil system provides an excellent packaging solution for a full range of conduit sizes. Our range of payoffs and takeups provide stable manufacturing handling equipment for forming and extrusion coating operations.

Tele/Data Communications

Telecommunications has changed over the past 30 years. The telecommunications industry used to center around copper cables of up to six or eight inches. Today the industry has leaped technologically into fiber based cable constructions of less than an inch that transmit many times the amount of voice and data once carried on those old copper cables. Telecommunications has merged into what is now considered datacommunications. This world has changed dramatically and become supported by those cables including Category, Coax, Fiber and RF. These cables support your voice and data needs be it in the office, home or via your mobile phone. All along this market, The MGS Group has machines engineered to provide rugged and robust solutions for the manufacturing operations.

Electron Beam Processing

Some insulated wires are made with electron beam processing of the polymers coating the wire. The electron beam process crosslinks or cures the polymer coating the wire to achieve durability desired by end users of the wire. Pictured here is a purpose built under beam capstan machine that exposes the multiple wraps of the wire around the capstan wheels to the e beam. The wire insulation requires a certain amount of time in front of the beam for crosslinking of the polymer. The MGS Group worked with industry leaders to develop this application specific solution for this demanding and technical requirement.

Specialty Wires

RF cables support high bandwidth comSpecialty wires are basically those wires that are engineered to a customer’s requirement. These wires are most often similar to other wires and cables in other markets, then modified to meet specific engineering challenges in a specific application. These applications often develop into large markets for wire processors that focus their attention on individualized needs rather than more commodity products. Some of these products are produced in relatively small quantities in plants specialized in “short run” or “job shop” environments. Many of these products ultimately become high quantity products of tomorrow. Key machine characteristics for this market are flexible machine designs that can adapt to the continuously changing production requirements which is a trademark of The MGS Group engineered excellence.munications networks. Basically, the king of coaxial cables, the RF Cable construction are demanding in many respects. The cable is often times a foamed construction requiring specialized techniques and process know how. The handling of the cable in manufacture requires steady and consistent movements to insure the cable performance. The MGS Group machinery has insured smooth and steady cable handling throughout these processes. We have provided a range of payoffs, takeups and capstans for applications in this field.