The MGS Group offers BUNCHERS / CABLERS / STRANDERS

Bunchers, stranders and cablers take individual strands or cables and form them into desired geometric configurations. These machines support processing requirements in bare wire, building wire, power cable and data communications cables.

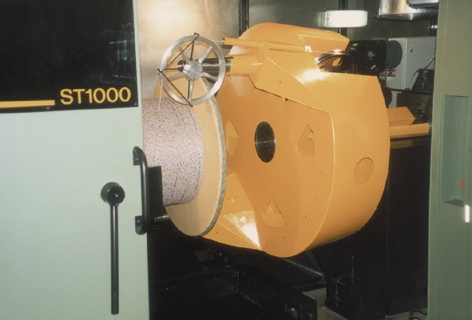

SINGLE TWIST

The Single Twist machine utilizes an aerodynamic rotor, rotating around a traversing take up drum mounted on a cantilever shaft. This machine is ideally suited to manufacture the high specification data/communication cables required by today’s cable manufacturers. With the emphasis on aerodynamic components such as the rotor and the final guide pulley, the vibration and noise levels are kept to a minimum.

Please Login to download the ST800 PDF Please Login to download the ST1000 PDF

DOUBLE TWIST

The MGS Group / Northampton Machine Double Twist Machines are devoted to precise tension control of the wire during its passage to the final winding of the twisted product onto its reel. The rugged reliability of these systems have driven success in demanding bare and insulated wire applications.

Please Login to download the B560 PDF Please Login to download the B630 PDF Please Login to download the SLB800 PDF

Please Login to download the SLB1000 PDF Please Login to download the SLB1250 PDF Please Login to download the SLB1600 PDF

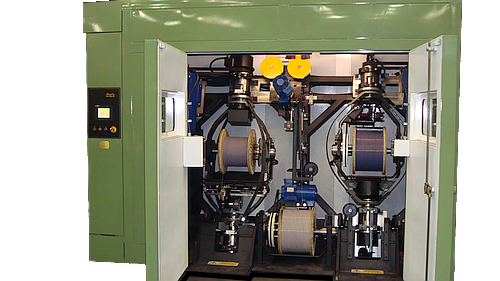

TRIPLE TWIST

This exceptional design combines Northampton’s 630mm Double Twist Twinner with two 560mm (or 600mm) dancer controlled payoffs, efficiently positioned in a single enclosure.

Please Login to download the Triple Twist PDF